Corrosion Resistant Floor Coating

Floor corrosion is a very common problem for industrial and commercial facilities. Not only is corrosion an eyesore, it can cause hazardous conditions for employees, visitors and the environment alike.

Concrete corrosion can actually impact the ground beneath the concrete surface, exposing the building and inhabitants to environmental hazards. Since concrete is a porous material, some toxic substances can actually leach through the slab into the ground beneath. From there, toxic chemicals can enter the groundwater. This not only impacts the facility and surrounding environment, but also impacts costs to remediate the problem.

Causes of Corrosion

Corrosive Chemicals

Exposure to corrosive chemicals such as acids, alkalis, and salts can lead to corrosion of industrial floors. These chemicals can chemically react with the floor’s surface, causing degradation and damage.

Chemical Spills

Accidental or improper handling of chemicals can result in spills on the industrial floor. When left untreated, these chemical spills can corrode the floor over time.

Moisture and Humidity

Excessive moisture and high humidity levels can contribute to corrosion, especially on concrete floors. Water can penetrate the concrete, leading to the formation of rust in reinforcing steel or other metal components.

Abrasion and Wear

Heavy machinery, equipment, and foot traffic can cause abrasion and wear on the floor’s surface, removing protective coatings and exposing the underlying material to corrosion.

Temperature Fluctuations

Extreme temperature variations can cause expansion and contraction of the floor material, potentially leading to cracks and openings where corrosive agents can penetrate.

Microbial Growth

Microorganisms like bacteria and fungi can thrive in certain industrial environments and produce corrosive byproducts, which can deteriorate the floor surface.

Poor Surface Coatings

Inadequate or damaged surface coatings can leave the floor vulnerable to chemical exposure and corrosion.

Electrical Activity

Electrochemical reactions can occur in certain industrial processes, leading to corrosion if not properly managed and grounded.

Impact Damage

Physical impact from dropped objects or heavy loads can cause damage to the floor’s surface, creating openings for corrosion to occur.

Inadequate Maintenance

Lack of regular cleaning, maintenance, and protective measures can accelerate the corrosion process and reduce the floor’s lifespan.

Environmental Factors

Environmental factors such as pollution, airborne contaminants, and exposure to harsh weather conditions may lead to corrosion.

Incorrect Material Selection

Choosing the wrong flooring material for a specific industrial application can lead to premature corrosion if the material is not a chemically resistant floor.

Understanding and addressing these potential causes of corrosion is essential to maintaining the integrity and safety of industrial floors.

Problems Caused By Corrosion

Structural Weakening

Corrosion can compromise the structural integrity of industrial floors, leading to weakening and potential safety hazards.

Surface Damage

Surface damage is often a result of corrosion, including cracks, pitting, and flaking of the floor material.

Safety Risks

Floors can become slippery and hazardous when corroded, increasing the risk of slips, trips, and falls for workers.

Reduced Load-Bearing Capacity

Corrosion-induced damage can reduce the load-bearing capacity of industrial floors, limiting the weight they can support.

Equipment Damage

Equipment and machinery damage is a result when the corrosive agents affect the bases or supports of these assets.

Increased Maintenance Costs

Regular maintenance and repairs become necessary to address corrosion-related issues, leading to higher operational costs.

Production Downtime

Repairs and maintenance required to address corrosion can lead to production downtime, resulting in financial losses for businesses.

Environmental Concerns

Corrosive substances that leach into the environment due to floor corrosion can lead to environmental contamination and regulatory issues.

Reduced Lifespan

Corrosion can significantly reduce the expected lifespan of industrial floors, necessitating premature replacement or extensive repairs.

Aesthetic Degradation

Corroded floors can give an unprofessional and deteriorated appearance to industrial facilities, affecting their overall aesthetics.

Health Risks

In some cases, the corrosion process may release harmful substances or fumes, posing health risks to workers and occupants.

Operational Disruptions

Corrosion-related problems may necessitate temporary shutdowns or reconfiguration of workspaces, disrupting daily operations.

Impact on Product Quality

In industries where product quality is critical, corrosion-related issues can affect the quality of products being manufactured or stored.

Increased Maintenance Frequency

Ongoing corrosion issues may require frequent and costly maintenance efforts to prevent further deterioration.

Safety Compliance Issues

Corroded floors may fail to meet safety and regulatory standards, leading to compliance issues and potential legal consequences.

Addressing corrosion on industrial floors is essential to mitigate these problems and maintain a safe, efficient, and cost-effective working environment.

Time to remediate the problems can also become a major factor if the corrosion is not addressed relatively quickly. Downtime can be considerable which results in lost revenue.

Prime Polymers is a single-source, turnkey provider of exceptional industrial flooring systems, including corrosion resistant floor coatings. We have outfitted hundreds of thousands of square feet of industrial flooring systems over the last 2 decades.

Our team of flooring experts carefully and thoroughly assess your facility to determine the most optimal flooring solution for your unique requirements. Our goal is to deliver the best product, with as little downtime and expense possible.

This business practice has garnered Prime Polymers rave business reviews and hundreds of referrals.

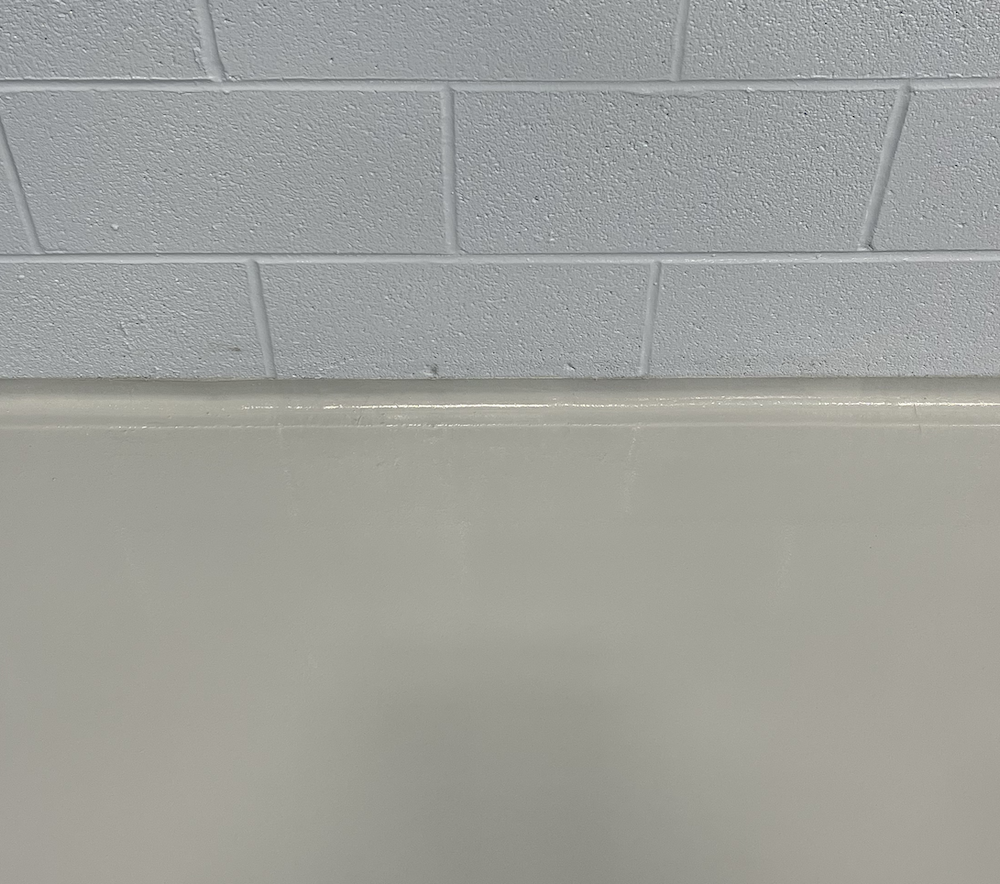

Prime Polymers’ corrosion resistant flooring systems are fluid applied to the concrete substrate. Our flooring systems are virtually impervious to corrosive substances. When toxic substances are spilled, our flooring systems enable the spill to be cleaned up rather than being absorbed, and thus considerably reducing the likelihood for corrosion to occur.

Benefits of Prime Polymers’ Corrosion Resistant Flooring Systems

Manufactured and Installed by Prime Polymers

When it comes to chemical resistant flooring, you can trust Prime Polymers for our expertise in both manufacturing and installation. Our experience ensures that your facility benefits from a professionally executed flooring solution that is engineered to withstand harsh chemicals.

Seamless

Prime Polymers’ corrosion resistant floors feature a seamless design that eliminates joints or seams. This not only enhances the aesthetics of your workspace, but also prevents the infiltration of corrosive substances, offering maximum protection against aggressive chemicals.

Anti-Slip Protection

Safety is paramount, and corrosion resistant flooring includes effective anti-slip properties. This feature significantly reduces the risk of accidents, especially in areas susceptible to spills or moisture.

Abrasion Resistant

These floors are engineered to be highly abrasion resistant, capable of enduring the wear and tear caused by heavy machinery, equipment, and foot traffic. This exceptional durability ensures that your flooring system remains intact even when subjected to harsh chemicals.

Durable

Corrosion resistant floors are renowned for their durability, making them an excellent choice for industrial settings. They can withstand the most demanding conditions, providing a long-lasting and reliable surface that requires minimal maintenance.

Corrosion Resistant Epoxy

Advanced corrosion-resistant epoxy coating adds a robust barrier against corrosive agents, offering maximum protection against chemical corrosion and chemical attacks.

Ease of Maintenance

Maintaining these corrosion resistant floors is straightforward due to its smooth surface and resistance to stains. This makes them easy to clean and maintain, reducing downtime and maintenance costs for your facility.

Water-Based Epoxy Coating

Prime Polymers’ use of a water-based epoxy coating adds an environmentally friendly dimension to our flooring systems. This coating not only enhances the floor’s resistance to aggressive chemicals, but also aligns with sustainable practices.

Call Prime Polymers today to schedule an exhaustive assessment of your facility and a free quote. Our industrial flooring experts will help recommend the right flooring solution for you!