Low Odor Epoxy Coating Systems For Commercial and Industrial Facilities

Prime Polymers’ low odor epoxy floor coatings offer an excellent solution for any industrial or commercial facility. We understand the importance of low odor flooring systems because we have manufactured and installed them for more than 2 decades!

No facility wants to disrupt the work day by disturbing its employees and visitors with a bothersome odor.

Causes of Odors

Spills and Stains

Accidental spills of harsh chemicals or volatile organic compounds (VOCs) on concrete floors can lead to persistent odors if not properly cleaned and deodorized.

Poor Cleaning Practices

Inadequate cleaning routines can allow dirt, grime, and noxious chemical to accumulate, resulting in very unpleasant odors that are difficult to remediate.

Microbial Growth

Moisture or humidity on concrete floors can create conditions conducive to the growth of mold, mildew, and bacteria. Bacteria can and will produce foul odors, and in some cases can be chemical resistant making it very difficult to remove.

Decaying Organic Matter

In industrial settings, organic materials such as food or plant debris may find their way onto facility floors and decompose, resulting in extremely bad odors.

Oil and Chemical Spills

Leaks, oil spills, acid, chemicals, solvents and other products in industrial environments can emit strong and often noxious odors, exacerbated by hot tire pickup.

Inadequate Ventilation

Poor airflow can trap odors indoors, making them more noticeable and persistent, especially in poorly ventilated warehouses and industrial plants.

Waste Disposal

Improper disposal of waste, especially hazardous materials, can result in odors that permeate the facility. This is another reason to coat the floors with low odor, low VOC epoxy flooring systems.

Sewer or Plumbing Issues

Malfunctioning plumbing systems or sewer problems are tough and can cause sewage odors to emanate from floor drains or pipes. Cracks can form and adversely impact facility floors and industrial garage floor as well.

Animal and Pest Infestations

In some cases, pests such as rodents can die beneath the flooring, resulting in very unpleasant odors as they decompose.

Chemical Reactions

In chemical processing or manufacturing facilities, chemical reactions can produce odorous byproducts and harmful fumes that can affect the surrounding areas.

Lack of Routine Maintenance

Neglecting regular maintenance of concrete floors can lead to deterioration and odor, particularly in industrial settings with heavy machinery and chemical exposure.

Construction or Renovation Residue

Leftover construction materials, dust, or adhesive residue from previous projects, can emit odors when disturbed.

HVAC System Issues

Problems with heating, ventilation, and air conditioning systems can distribute smells throughout a building, including smells from sources outside.

Cross-Contamination

In food processing facilities, cross-contamination between products or ingredients can lead to a mix of odors, resulting in unpleasant smells.

Product Off-Gassing

Some industrial products, such as adhesives, paints, or coatings, can release VOCs that contribute to indoor odors.

Humidity and Moisture Issues

High humidity levels or water leaks can cause concrete floors to absorb moisture, promoting microbial growth and generating musty odors.

Chemical Storage

Improperly stored chemicals or incompatible chemical combinations can release noxious fumes and odors, requiring careful consideration for implementing chemical resistance measures.

To effectively address floor odors in commercial and industrial settings, it’s crucial to identify the specific cause. Then, implement appropriate cleaning, maintenance, and ventilation measures while considering the potential impact of volatile organic compounds and harsh chemicals.

Advantages of Low Odor Flooring

Odor occurs during the chemical curing process and typically proper ventilation/airflow is a viable solution, but some areas may not be able to ventilate properly. Prime Polymers’ low odor flooring systems is a perfect solution!

Minimal Downtime

Our flooring systems are low odor, have efficient curing times with minimal emissions, allowing businesses to resume operations quickly. This is especially beneficial in industries where any interruption can result in significant financial losses.

No Disruption of Operations or Shut-Downs

The seamless integration of a low odor floor coating within the flooring system ensures that ongoing operations continue without any interruption. No need to shut down sections of a facility or disrupt workflow during installation.

No Expensive Rescheduling of Workdays

Thanks to the lower odor properties of our flooring system, there’s no need to incur expenses associated with rescheduling workdays or production shifts to accommodate flooring installation.

Far Less Distraction to Employees and Visitors

A high-performance low odor flooring system is designed to emit minimal or no unpleasant smells during and after installation. This minimizes distractions and discomfort for employees, visitors, and customers, allowing them to focus on their tasks without being affected by noxious odors.

100% Epoxy Coating

As a part of the flooring system, the clear coat used is 100% epoxy coating. This delivers a durable, seamless, and chemically resistant surface, making it a great topcoat for industries where chemical spills or heavy machinery use are common.

Moisture Cured Urethanes with Up to 90% Plus Solids

Some components of the low odor flooring system include moisture-cured urethane compounds with high solids content. These materials are incorporated into the first coat, ensuring a robust, moisture-resistant, and low-odor flooring system suitable for various industrial and commercial settings.

Meets USDA Requirements

Low odor flooring systems are engineered to meet USDA requirements, making them suitable for facilities in the food processing or agricultural sectors. These flooring systems are easy to clean and maintain while also providing moisture and chemical resistance.

Moisture Vapor Mitigating

The flooring system’s moisture vapor mitigation capabilities are crucial for areas where moisture issues are a concern. This feature is often integrated into the top coat, helping to prevent moisture-related problems like mold, mildew, and substrate damage, all while emitting minimal odors.

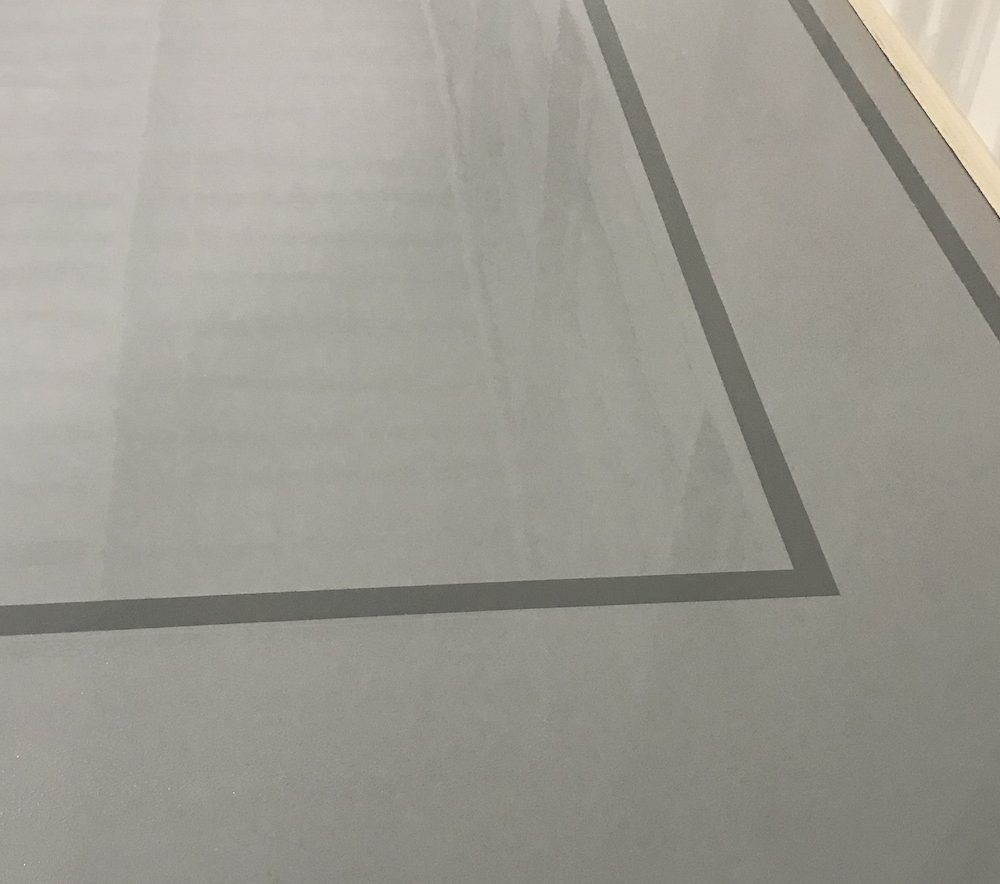

Solid Color or Colored Chip Floors

Low odor flooring systems also offer the choice of solid color or colored chip finishes as part of the top coat. This customization allows businesses to select a flooring style that matches their aesthetic preferences or brand identity, while maintaining low odor levels during installation.

A high-performance, low odor flooring system offers several advantages, including efficient curing times, seamless integration within operations, and cost savings. Also, improved comfort for employees and visitors. A durable 100% epoxy clear coat, moisture-resistant properties through the first coat, compliance with regulatory requirements (such as USDA), moisture vapor mitigation in the top coat, and customizable aesthetic options. These benefits make our low odor flooring system an excellent choice for various commercial and industrial settings.

Call Prime Polymers today to discuss your low odor flooring requirements. Our highly experience team will thoroughly evaluate your facility and provide recommendations based on your needs and budget!

Prime Polymers has been an industry leader in industrial flooring systems since 1994. Our high quality products and exceptional work ethic has enabled our business to grow because of customer referrals. There is no greater recognition of great work than a customer referral! We would be happy to provide referrals upon request.