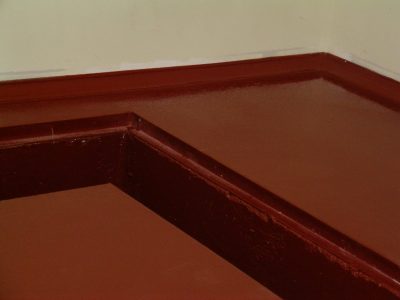

Commercial Epoxy Flooring Systems

Commercial epoxy flooring is a resilient and versatile flooring solution that involves applying an epoxy coating to concrete floors, covering the entire surface. This specialized epoxy coating, sometimes mistakenly referred to as an epoxy paint, forms a seamless and glossy finish that chemically bonds to the concrete. Its benefits make it an excellent choice for commercial properties.

Epoxy flooring boasts exceptional durability, capable of withstanding heavy foot traffic, machinery, and vehicular loads. This makes it suitable for various commercial environments, from warehouses to showrooms. Its superior resistance to chemicals, stains, and spills is vital for businesses dealing with liquids like oil and solvents. The easy-to-clean, seamless surface prevents damage to the underlying concrete and reduces maintenance costs.

Professional installation ensures a consistent and durable finish. Our commercial epoxy flooring systems offer longevity and aesthetics, making them a practical and visually appealing choice for enhancing commercial properties.

Urethane Concrete

Urethane concrete is an advanced flooring system designed to provide superior durability and protection for concrete surfaces. It is a type of floor coating that combines the benefits of epoxy floors with the added strength and resilience of urethane, making it an ideal choice for a wide range of applications on concrete floors. Advantages of using urethane concrete flooring:

Exceptional Durability

Urethane concrete offers exceptional durability, with the ability to withstand heavy traffic, impact, and abrasion. This makes it a suitable choice for industrial facilities, commercial kitchens, and other high-traffic areas where concrete surfaces are subjected to significant wear and tear.

Chemical Resistance

Urethane concrete provides excellent resistance to a variety of chemicals, including acids, solvents, and oils. This chemical resistance ensures that the flooring remains intact and unaffected by potentially corrosive substances, making it ideal for settings where spills are common.

Hygienic Surface

The seamless and non-porous nature of urethane concrete makes it easy to clean and maintain. This hygienic surface prevents the growth of bacteria and makes it suitable for use in food processing facilities, pharmaceutical labs, and healthcare settings.

Customization

Urethane concrete comes in a wide range of colors and finishes, allowing for customization to match the aesthetics of any space. This versatility enables businesses to create an appealing and brand-aligned environment for their employees and customers.

Ease of Installation

Urethane concrete can be installed efficiently by trained professionals. Applying epoxy typically involves surface preparation, including cleaning and repair, followed by the application of the urethane concrete coating to cover the square footage of the entire floor surface.

Urethane concrete is a versatile and high-performance flooring solution that offers exceptional durability, chemical resistance, ease of maintenance, and customization options. It is well-suited for various settings, from industrial facilities to commercial spaces, where concrete surfaces need to withstand the rigors of daily use while maintaining a clean and visually appealing appearance.

ESD

ESD (Electrostatic Discharge) epoxy systems are specialized coatings designed to provide electrostatic dissipation properties, making them essential for environments where static electricity control is critical. These flooring systems typically consist of multiple layers, including a prime coat, a floor epoxy with ESD properties, and a second coat. ESD epoxy flooring is commonly used in industries such as electronics manufacturing, clean rooms, and healthcare facilities where static electricity can damage sensitive equipment or pose safety risks to personnel. Advantages of using ESD epoxy flooring:

Static Control

The primary advantage of ESD epoxy flooring is its ability to dissipate static electricity. The high-performance epoxy in the system contains conductive or dissipative materials that allow static charges to safely flow to the ground. This prevents electrostatic discharge that could damage electronic components or create sparks in explosive environments.

Durability

ESD epoxy flooring is known for its durability and resistance to heavy traffic, chemicals, and abrasion. The multiple layers, including the prime coat and second coat, create a robust and protective surface that can withstand the rigors of industrial and commercial environments.

Easy Maintenance

These flooring systems are relatively low-maintenance. They offer a smooth, easy-to-clean surface that resists staining and is compatible with common cleaning agents. This ease of maintenance reduces the need for costly upkeep and enhances the longevity of the flooring.

Seamless Finish

The application of ESD epoxy flooring creates a seamless finish across the entire floor surface, eliminating gaps or joints where dirt and contaminants could accumulate. This seamless quality simplifies cleaning and contributes to a more hygienic environment.

Safety

In sensitive environments, such as laboratories or manufacturing facilities, where the risk of static-related accidents is a concern, ESD epoxy flooring enhances safety. It reduces the potential for personnel to experience static shocks and minimizes the risk of damaging electronic equipment.

ESD epoxy systems are essential in environments where static electricity control is paramount. They provide static control, durability, ease of maintenance, a seamless finish, and safety benefits.

High Temperature

High-temperature epoxy novolac is a specialized type of epoxy flooring system engineered to withstand extreme heat and chemical exposure. It is commonly used in industrial settings where conventional flooring materials would deteriorate under such harsh conditions. This flooring solution typically involves the application of multiple layers, including a primer coat, epoxy mixes, and epoxy coatings, which combine to create a robust and heat-resistant floor surface. Advantages of using high-temperature epoxy novolac flooring:

Heat Resistance

One of the primary advantages is its exceptional heat resistance. This flooring can endure high temperatures, making it ideal for industries where processes generate intense heat, such as foundries, chemical plants, and commercial kitchens. It maintains its structural integrity even when exposed to extreme thermal conditions.

Chemical Resistance

High-temperature epoxy novolac is highly resistant to a wide range of harsh chemicals, acids, and solvents. This quality ensures that the flooring remains unaffected by chemical spills or exposure, reducing the risk of corrosion and damage.

Durability

This flooring system is renowned for its durability. It can withstand heavy traffic, impact, and abrasion without showing signs of wear and tear. Its longevity minimizes the need for frequent maintenance and replacements.

High-temperature epoxy novolac flooring is an indispensable solution for industries where extreme heat and chemical exposure are constant challenges. Its heat resistance, chemical resistance, durability, use of epoxy coatings, and quick installation turnaround make it an excellent choice for maintaining safe and reliable flooring in the most demanding environments. We can install epoxy flooring that can withstand the harshest conditions and provide long-lasting performance.

Chemical Resistant

Our chemical epoxy coatings are a specialized type of flooring solution designed to provide exceptional chemical resistance, making them well-suited for various industrial and commercial applications. Our coatings consist of multiple layers, including epoxy floor coatings that create a durable and protective surface. Chemical epoxy is particularly effective in environments where exposure to chemicals, oils, and other corrosive substances is common. Advantages of using chemical epoxy flooring:

Chemical Resistance

The primary advantage of chemical epoxy floors is their exceptional resistance to a wide range of chemicals and corrosive substances. They can withstand exposure to acids, solvents, oils, and grease stains without deteriorating or becoming damaged.

Durability

These coatings are highly durable and can endure heavy traffic, impact, and abrasion. This durability ensures that the flooring maintains its structural integrity and appearance over time, reducing the need for frequent maintenance or replacement.

Top Coat

Chemical epoxy flooring often includes a top coat, which serves as an additional layer of protection. The top coat enhances the floor’s resistance to chemicals and provides a glossy finish that is easy to clean and maintain.

Chemical epoxy coatings are a versatile flooring solution known for their exceptional chemical resistance, durability, top coat protection, and suitability for garage floors. Their ability to withstand exposure to corrosive substances, including grease stains and chemicals, makes them a reliable choice for industrial and commercial environments where maintaining a safe and resilient floor is essential.

Penetrating Sealers

Penetrating sealers using the Ashford formula are designed to enhance the durability and protection of concrete. This unique formula involves a multi-step application process that includes acid etching, a base coat, and the use of a stiff bristle brush. The Ashford formula penetrates deep into the concrete, creating a strong bond and providing long-lasting benefits to every square foot of the floor. Advantages of using penetrating sealers with the Ashford formula:

Enhanced Durability

One of the primary advantages of this flooring treatment is its ability to significantly enhance the durability of concrete surfaces. The Ashford formula penetrates the concrete, strengthening it from within. This makes the floor more resistant to wear and tear from heavy traffic and daily use.

Protection Against Moisture

Penetrating sealers using the Ashford formula create a protective barrier that helps to repel moisture. This is particularly important for concrete surfaces that may be exposed to water or other liquids. The sealed surface prevents water penetration and potential damage such as cracking and spalling.

Stain Resistance

The treatment provides excellent resistance to stains and spills, making it easier to clean and maintain the appearance of the concrete floor. The protective layer prevents liquids, oils, and chemicals from seeping into the concrete, reducing the likelihood of unsightly stains.

Penetrating sealers using the Ashford formula offer enhanced durability, protection against moisture, stain resistance, and ease of application. The multi-step process involving acid etching, a base coat of epoxy, and the use of stiff bristle brushes ensures that the treatment effectively penetrates the concrete, resulting in a long-lasting and resilient floor surface.