Aviation Hangar Epoxy Floor Coating

Prime Polymers has served the floor resurfacing needs of the aviation industry for more than two decades. Our hangar flooring expertise, experience, and industry knowledge is second to none.

Prime Polymers’ hangar flooring systems deliver exceptional, long lasting results that surpass even the most stringent requirements and specifications demanded by the aircraft industry.

Our aviation flooring solutions are always aesthetically pleasing and deliver the best value. Our flooring ensures the utmost safety for the maintenance staff, pilots, passengers and the aircraft.

Prime Polymers has fulfilled the floor coating needs for the following aviation industries:

Epoxy flooring offers several advantages that make it particularly beneficial for various types of hangars. This includes commercial airline hangars, cargo hangars, corporate hangars, aerospace hangars, government hangars, military and defense hangars, and helicopter hangars. Here are some of the many benefits of epoxy floor coating, and why it is advantageous for these industries:

Commercial Airline Hangars

Durability: Commercial airline hangars handle a high volume of aircraft movements and maintenance activities. Epoxy flooring is highly durable and can withstand the heavy traffic, equipment, and chemicals used in maintenance, making it a cost-effective choice.

Cargo Hangars

Chemical Resistant: Cargo hangars may store and transport various goods, some of which can be corrosive or pose chemical risks. Epoxy flooring’s resistance to chemicals, oils, and solvents ensures the safety of both personnel and cargo.

Corporate Hangars

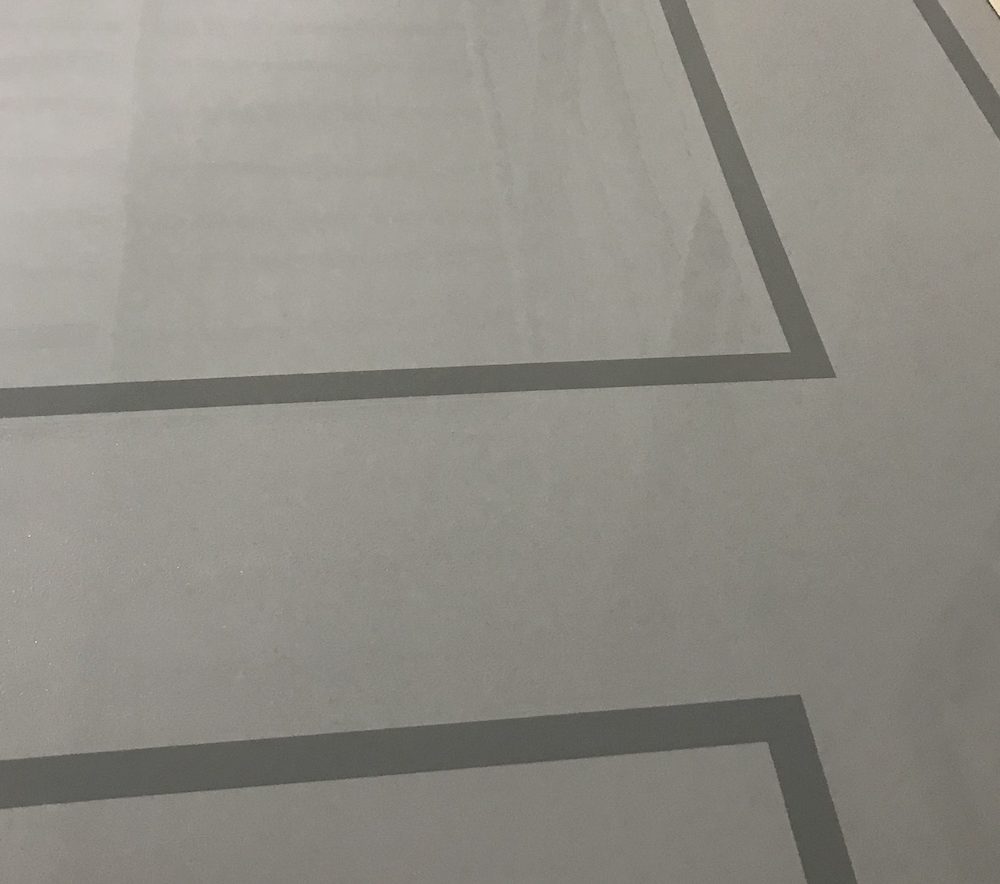

Aesthetics: Corporate hangars are often used for business meetings and events, and serve to showcase a private planes. As such, hangar epoxy floor coating is a great choice because it be customized to create an attractive and professional presentation. Installation of high performance epoxy with a high gloss finish will be beautiful, strong and slip resistant.

Aerospace Hangars

Maintenance Efficiency: Quick and efficient aircraft maintenance is essential for aerospace hangars. The smooth and seamless epoxy floor surface allows for easy movement of wheeled equipment, and the aircraft itself., thus streamlining maintenance processes.

Government Hangars

Longevity: Government hangars require durable flooring solutions to reduce maintenance costs and downtime. Prime Polymers’ epoxy flooring systems deliver exceptional wear resistance to ensure long-lasting performance and low maintenance.

Military and Defense Hangars

Security: Military hangars often house sensitive and costly aircraft and equipment. As such, protection against moisture, abrasion, chemicals, and static electricity is vital for these hangars. Prime Polymers’ hangar flooring systems are:

- Slip resistant

- Chemical resistant

- Electrostatic dissipative (ESD)

- Moisture resistant

- And we can customize your flooring with decorative striping & markings to enhance aesthetic appeal.

Helicopter Hangars

Spill Resistant: Fuel and hydraulic fluid spills are common occurrences in aviation hangars. These caustic liquids can damage standard flooring. Prime Polymers’ epoxy floor coating is resistant to fuel spills and can be easily cleaned so floor damage does not occur. This spill resistance also ensures safety and efficiency.

Epoxy flooring is a versatile and practical choice for aviation hangars. Its durability, chemical resistance, customization options, and ease of maintenance make it an ideal solution to meet the unique demands and requirements within the aviation industry.

Questions to Consider When Choosing Hangar Floor Coating:

- What is the weight-bearing capacity of the aircraft hangar flooring material, and will it support the aircraft?

- Does the flooring material offer resistance to chemicals, oils, and hydraulic fluids?

- Is the flooring easy to clean, and will it last for long-term concrete substrate durability?

- Can the flooring withstand heavy foot and equipment traffic?

- Does the flooring provide anti-slip properties to enhance safety in the hangar?

- Is the flooring solution fire-resistant for added safety?

- What is the expected lifespan of the flooring material?

- Can the floor coating system be customized with specific designs or markings?

- Does the flooring material meet regulatory and safety standards for aviation facilities?

Problems with Non – Epoxy Hangar Flooring:

Surface Wear and Tear

Standard industrial flooring may wear down quickly, leading to cracks, chips, and unevenness. This can make it difficult to move heavy equipment and machinery within the aircraft hangar, and can hinder the safety of on-site personnel and visitors.

Chemical Damage

Standard flooring materials take a beating from chemical, fuel, and oil spills. Airplane hangar floor coatings, such as epoxy flooring, provide resistance to these substances, whereas regular floors can quickly corrode or deteriorate.

Stains

Standard floors are porous, making them prone to staining after a spill occurs. Epoxy floor coatings are impermeable and easy to clean, thus reducing the risk of permanent staining. Low maintenance requirements, and thus lower maintenance costs are great benefits of an epoxy coating system.

Dust and Debris Accumulation

Non-durable flooring may not be sealed properly, allowing dust and debris to accumulate in cracks and crevices on the hangar floors. This can affect air quality, machinery performance, and overall cleanliness in the airplane hangars.

Slip Hazards

Aircraft hangar floors coated with epoxy reduce the risk of accidents and injuries caused by slippery surfaces. Regular industrial flooring does not offer the same level of slip resistance and safety.

Moisture Damage

Airplanes are exposed to moisture from various sources, such as weather conditions or washing the aircraft. Epoxy hangar floor coatings provide a waterproof and moisture-resistant barrier, while standard floors absorb moisture and are prone to cracking.

Abrasion and Impact Resistance

Heavy machinery and equipment movement is necessary for daily routine airplane maintenance. Durable epoxy flooring can withstand abrasion and impact, ensuring the hangar floor remains intact for many years.

Temperature Fluctuations

Aircraft hangars may experience extreme temperature fluctuations which can be detrimental to the floor. Epoxy floor coating can handle these temperature changes and prevent cracking or warping, whereas regular flooring may not.

Longevity and Durability

High-performance hangar floors typically have longer lifespans when compared to standard industrial flooring. The need for frequent floor repairs is highly disruptive for day to day hangar management.

Maintenance Costs

The need for frequent repairs and maintenance of standard floors can result in higher long-term costs when compared to the low maintenance requirements of durable epoxy coating.

Aesthetics

Epoxy aircraft hangar floor coatings offer a polished and professional appearance, which can positively impact the aesthetics of the airplane hangars. Standard hangar floors may look worn and unappealing, affecting the overall impression.

Compliance and Safety Regulations

There are regulatory requirements for hangar flooring materials, especially in terms of safety and environmental concerns. Non-compliance can result in fines and a host of legal issues.

Operational Efficiency

High-performance hangar flooring like epoxy, can enhance the efficiency of operations within the aircraft hangars. Uneven surfaces or damaged hangar floors can slow equipment movement and maintenance procedures.

Installation of durable flooring options such as epoxy coating, is essential to avoid potential problems, ensure safety, longevity, and operational efficiency for the long term

Call Prime Polymers today to discuss your hangar flooring project. Our comprehensive consultation and quote are always free of charge.